ADDITIONAL OPTIONS

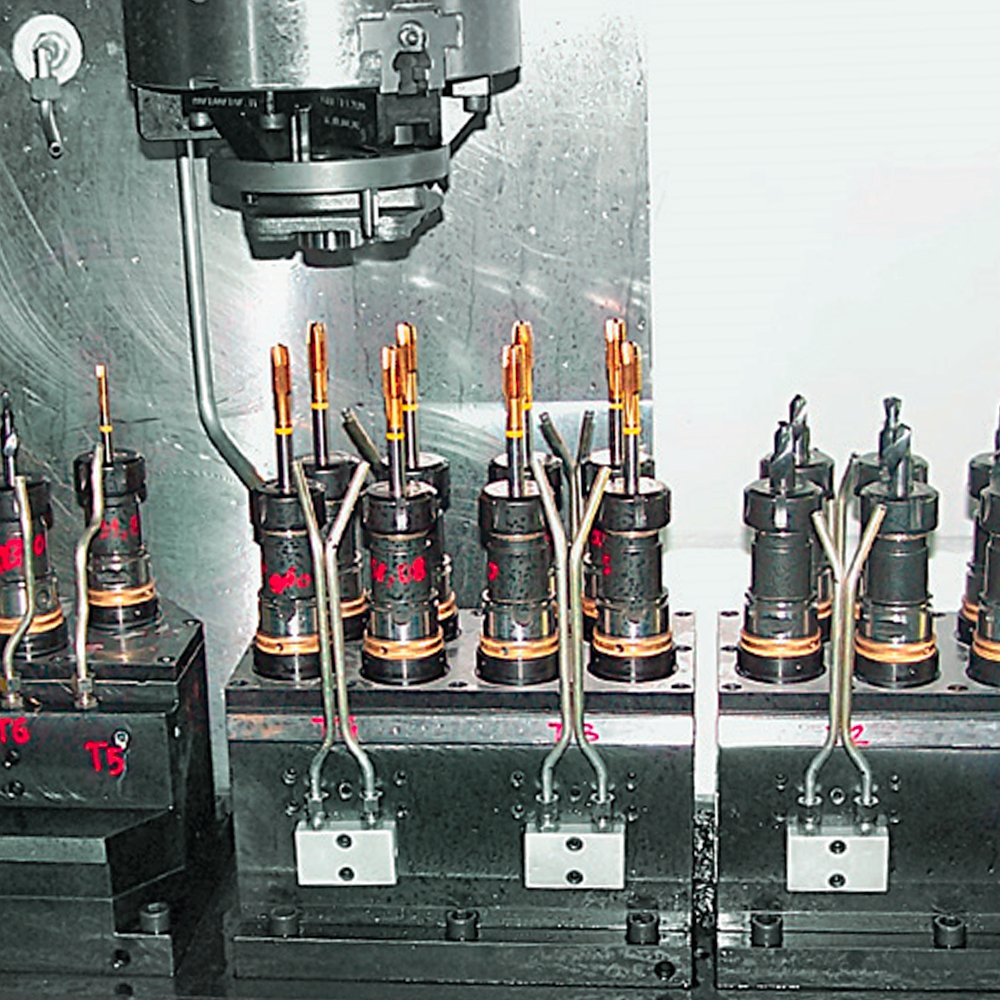

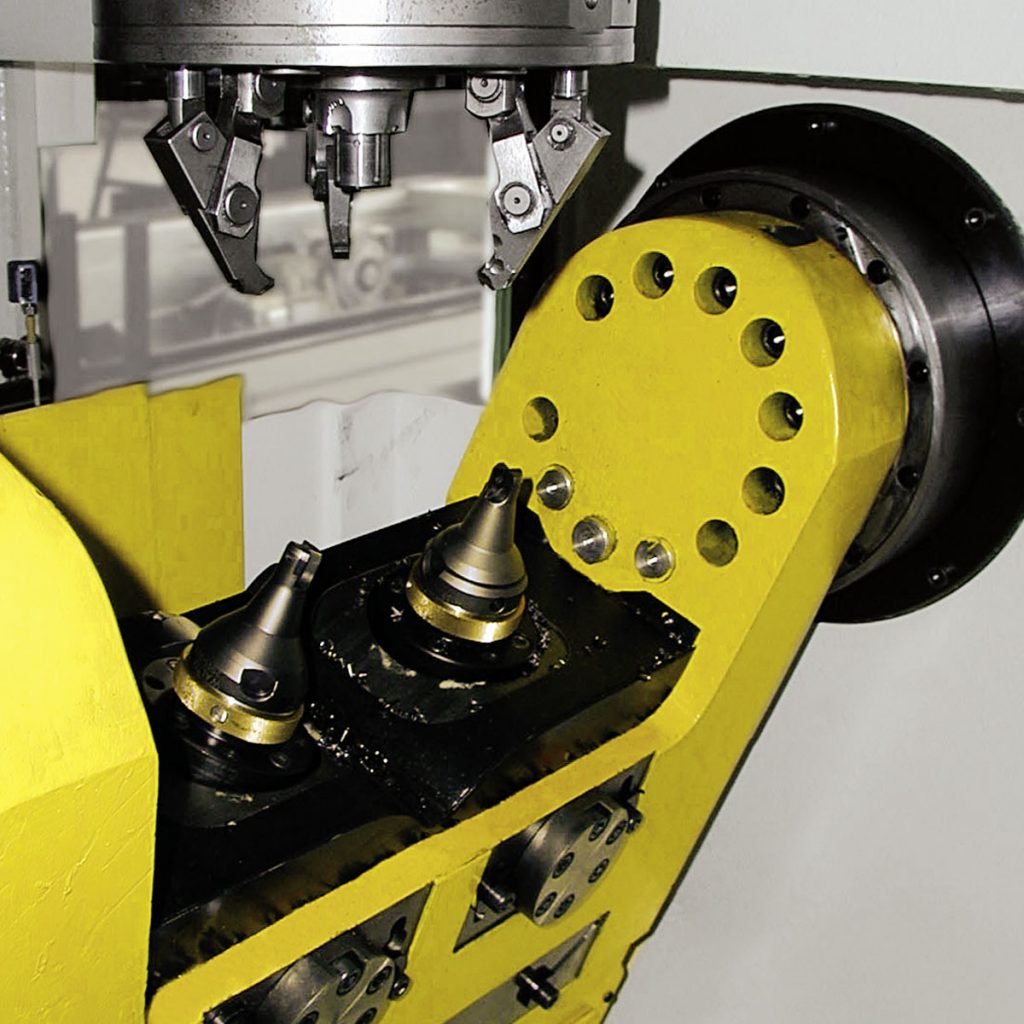

INFINITY OPTIONThe Infinity option provides for the replacement of the tool in a "masked" or “free” time during loading-unloading operations, making machine downtime nonexistent. |

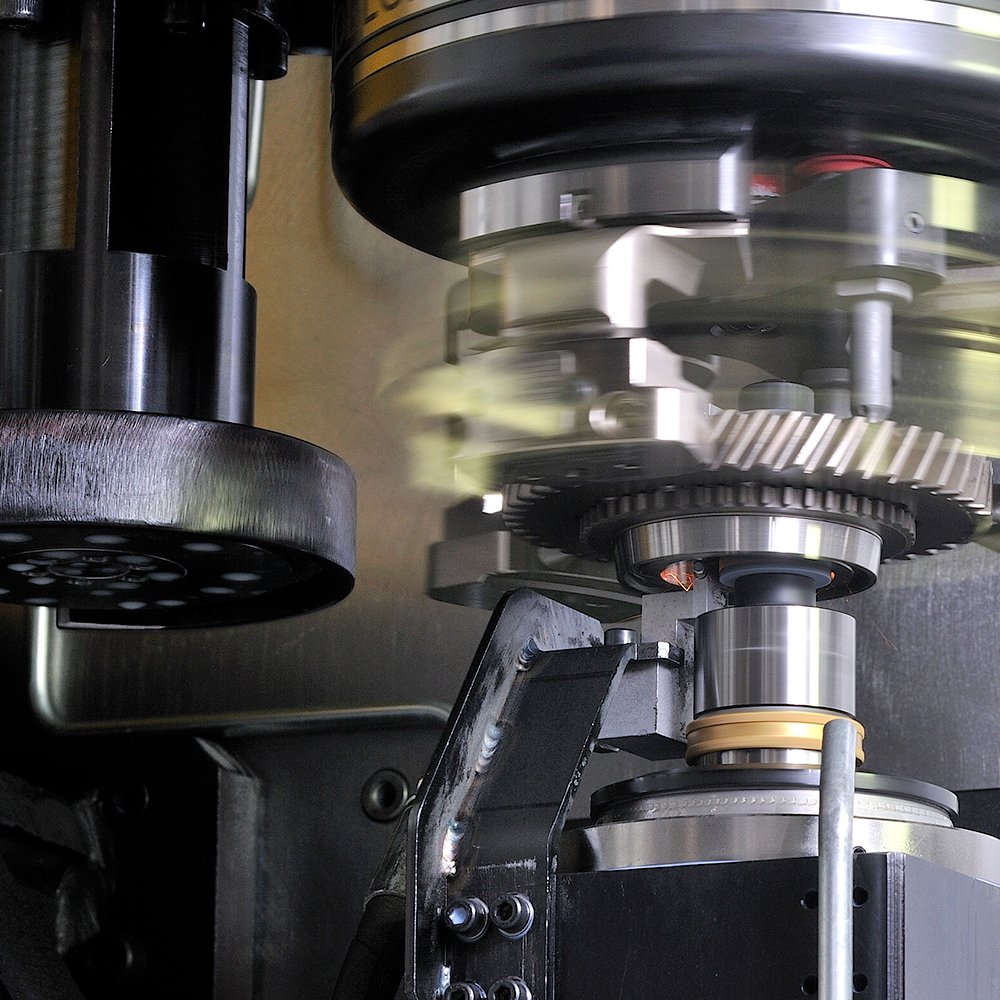

Z OPTIONThe Z option enables the workpiece to be turned and hobbed in one or two operations, thanks to the electrospindle gear hobbing or skiving support. |

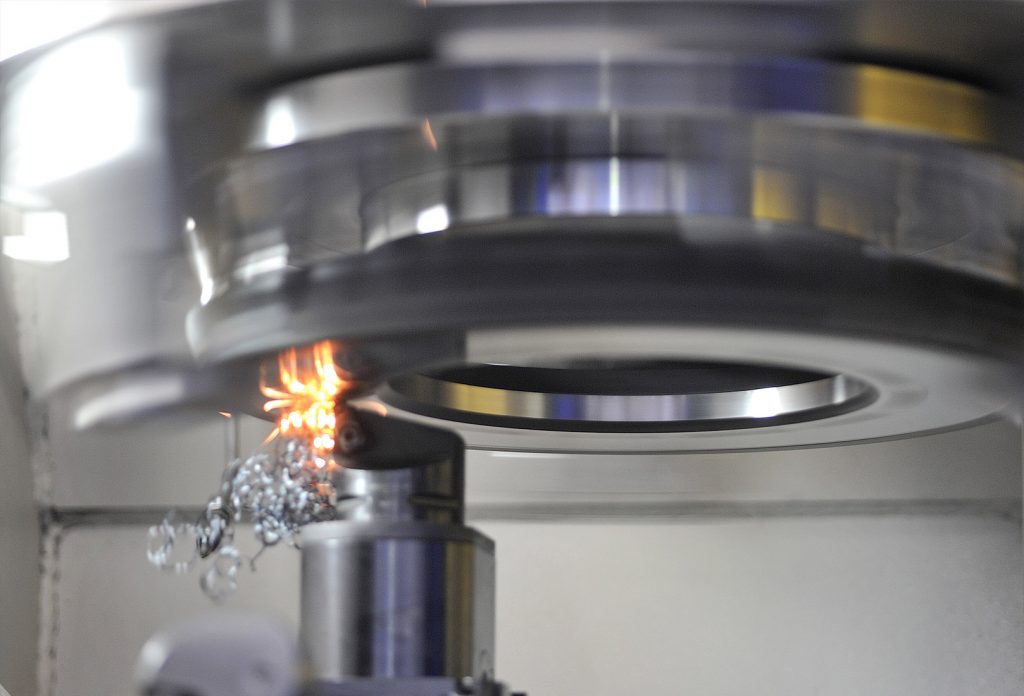

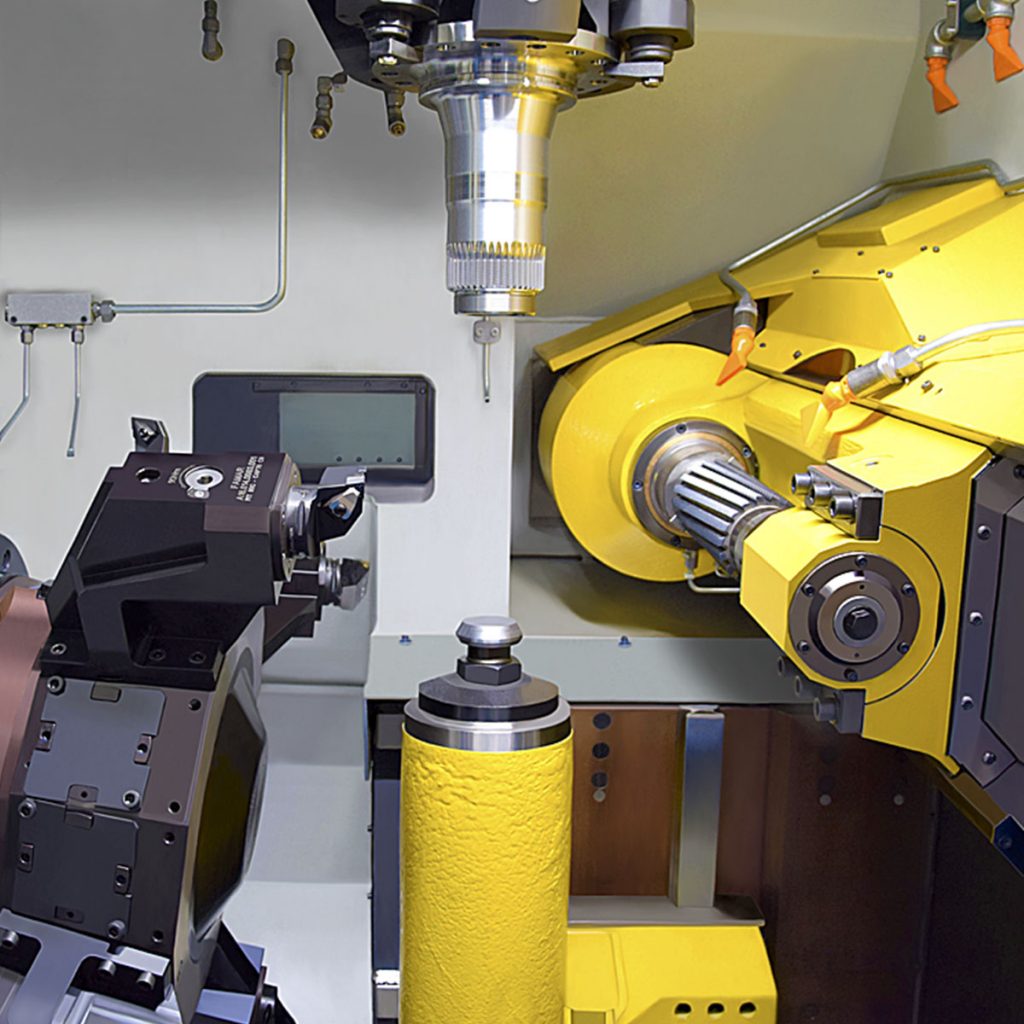

G OPTIONThe G option provides turning, grinding and diamond dressing using a ceramic or CBN wheel in a single operation. |

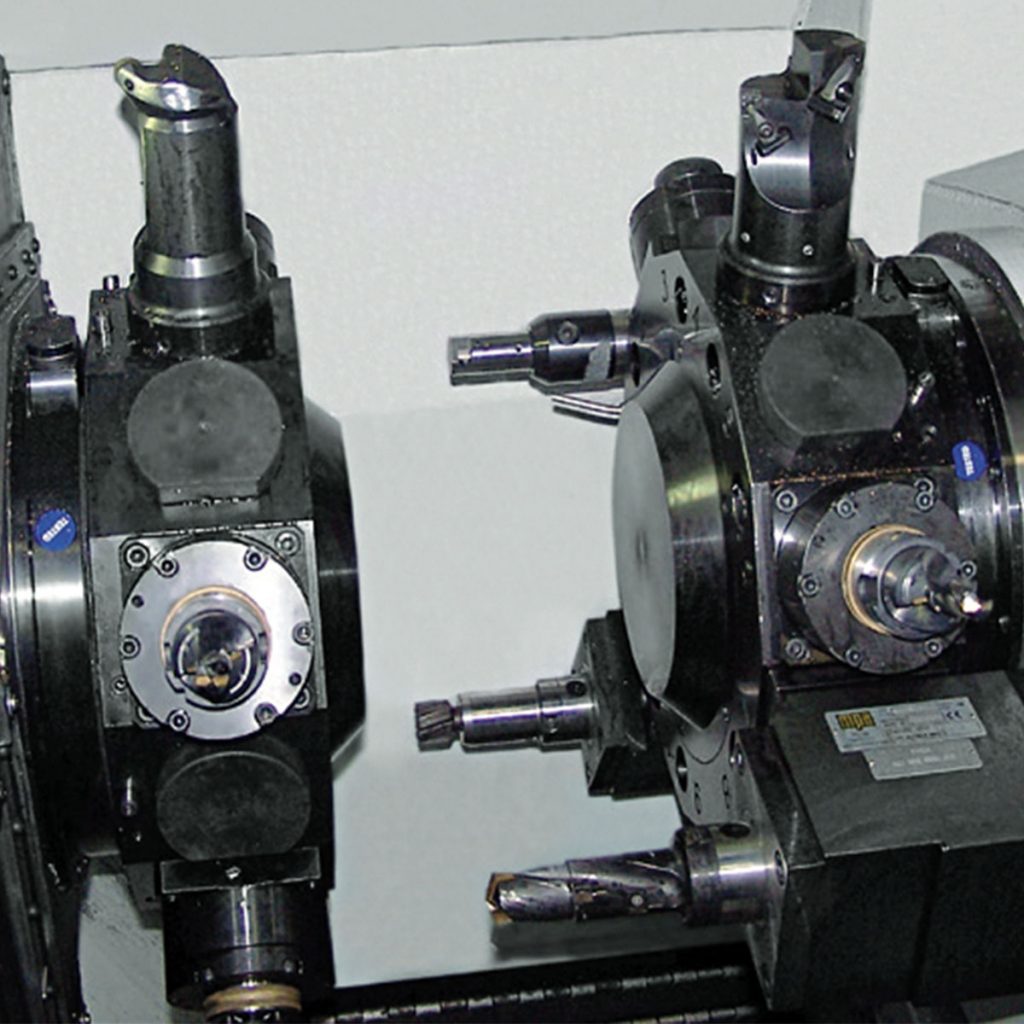

2T OPTIONThe 2T option allows drilling and tapping with different centre distances using a second driven turret by its own independent X1 axis. |

Y OPTIONThe Y option consists of a third axis that moves transversally the turret, allowing machining outside the rotational axis of the workpiece. |

L OPTIONOption L is an extended base frame designed to increase the working units on the machine by providing additional workpiece operations. |

SPECIAL SOLUTIONS

FCP SOLUTIONThe FCP solution includes an independent tailstock installed on the machine frame and a turret with an additional X1 axis. |

OT SOLUTIONThe OT solution allows non-cylindrical machining operations, such as oval turning of the piston with exceptionally high accuracy. |

DH SOLUTIONThe DH solution provides machining of the internal part of the differential housing ensuring incredible precision and productivity. |

MG SOLUTIONThe MG solution is characterised by the NC-controlled tilting cradle, which performs characteristic milling operations. |

MEASURING SYSTEMS

IN-PROCESS MEASURING SYSTEMThis system allows constant control of the dimensions realised and extreme stability of the machining process, automatically correcting tolerance deviations due to tool deterioration. |